Ramp Up!

Rapid Prototyping

Sometimes drawings on dinner napkins are where the next big idea generates! Rapid prototyping, also known as 3D printing, can help you get your product to the market faster!

We can help you turn your drawing and idea into a CAD model and get an in-hand 3D model rendering in as little as a day. Have an idea? Tell us about it here!

Prototyping

At Green World, our design team helps our customers bring their ideas to reality. While we offer rapid 3D Printing which is used to prototype parts, many of our customers need to take prototyping to the next level. Our prototype molding services can help you prepare for production runs by validating your product from base material, color, surface finish and function all the way to actual production efficiency.

Our project managers and engineers will work closely with you to understand your project's unique requirements and help you make informed decisions to optimize for the lowest costs and fastest lead times. Get started by clicking here to send us your inquiry!

The solution

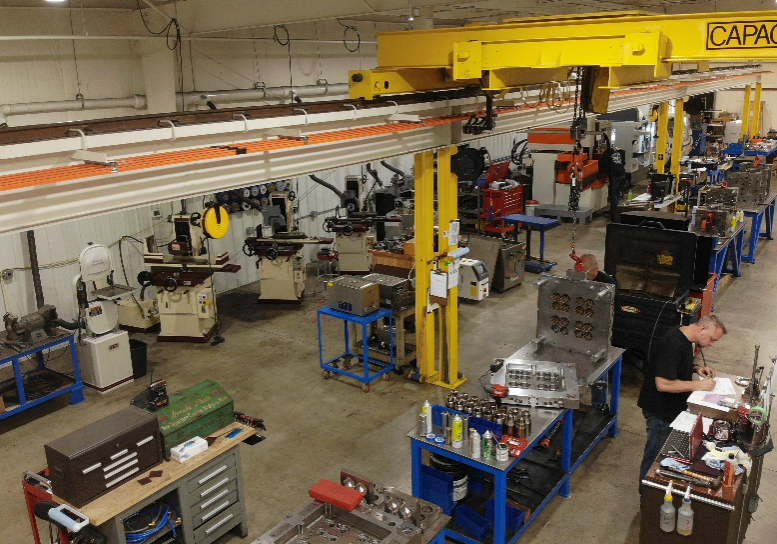

Steel Commercial Tooling

Building commercial tooling takes precision and time. It also represents one of the largest investments in the manufacturing process, so getting it right is critical to the success of a project.

It comes down to the details for cost and longevity of precision tooling. The details will always determine the quality of a precision mold built to last for years from the investment by your company.

Several variables impact the cost including:

Part complexity — In determining the cost of the mold, some complexities to consider would be, but not limited to, the surface finish, details, undercuts, engraving/embossing, testing, etc.

Cavity & Core Material — High volume class A are made from hardened steel that can withstand the pressures of a long production run while still meeting close tolerances

Cavity & Core Machining — All molds must be customized based on the part design and the machine it’s running in. Customization includes, but not limited to, the placement of cores, cavities, ejectors, cooling lines, etc.

Number of Cavities — We look to maximize cavitation in the mold to maintain the highest level of productivity without sacrificing quality.

Mold Base — The base holds all the mold cavities, inserts and components together. The cost of the base is determined based on the mold size, type of steel and gating options along with any additional and further customization.

Our design team works very closely with Quality, Tooling and Engineering to maximize efficiency without sacrificing the quality of your finished goods to offset cost and provide the best pricing and lead time possible.

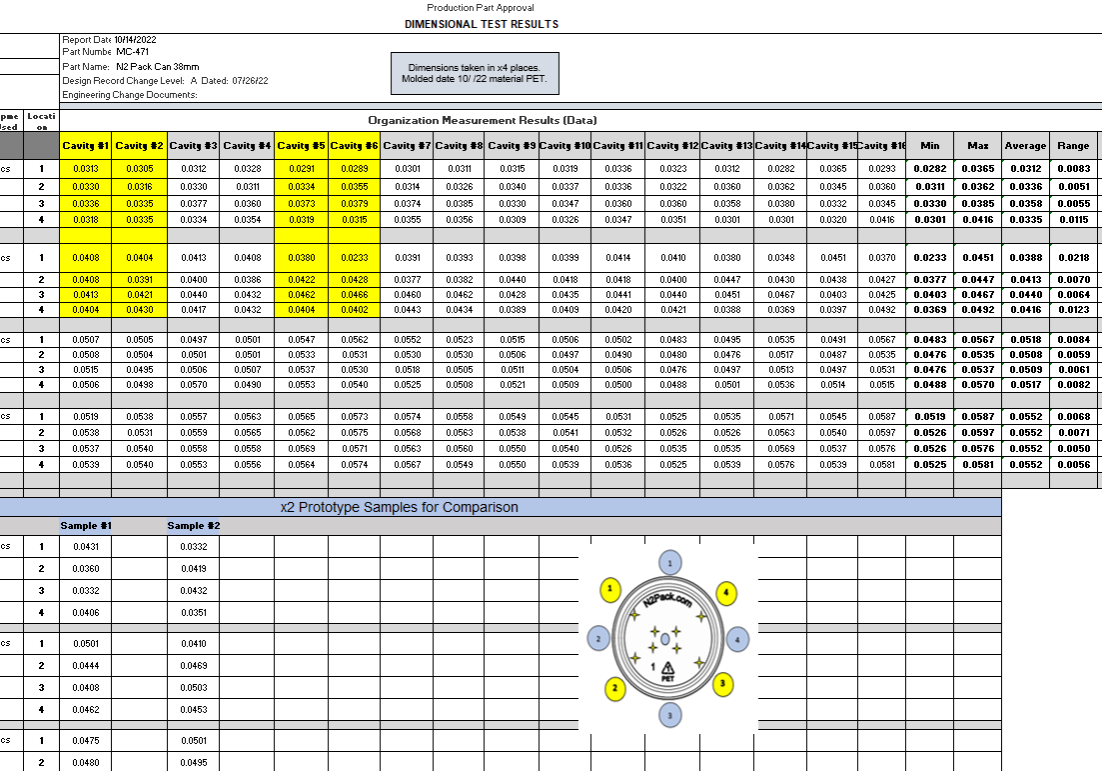

The results

Testing

Our team can assist you in reaching your goals of certifying your product through testing. We have assisted customers in getting testing for: